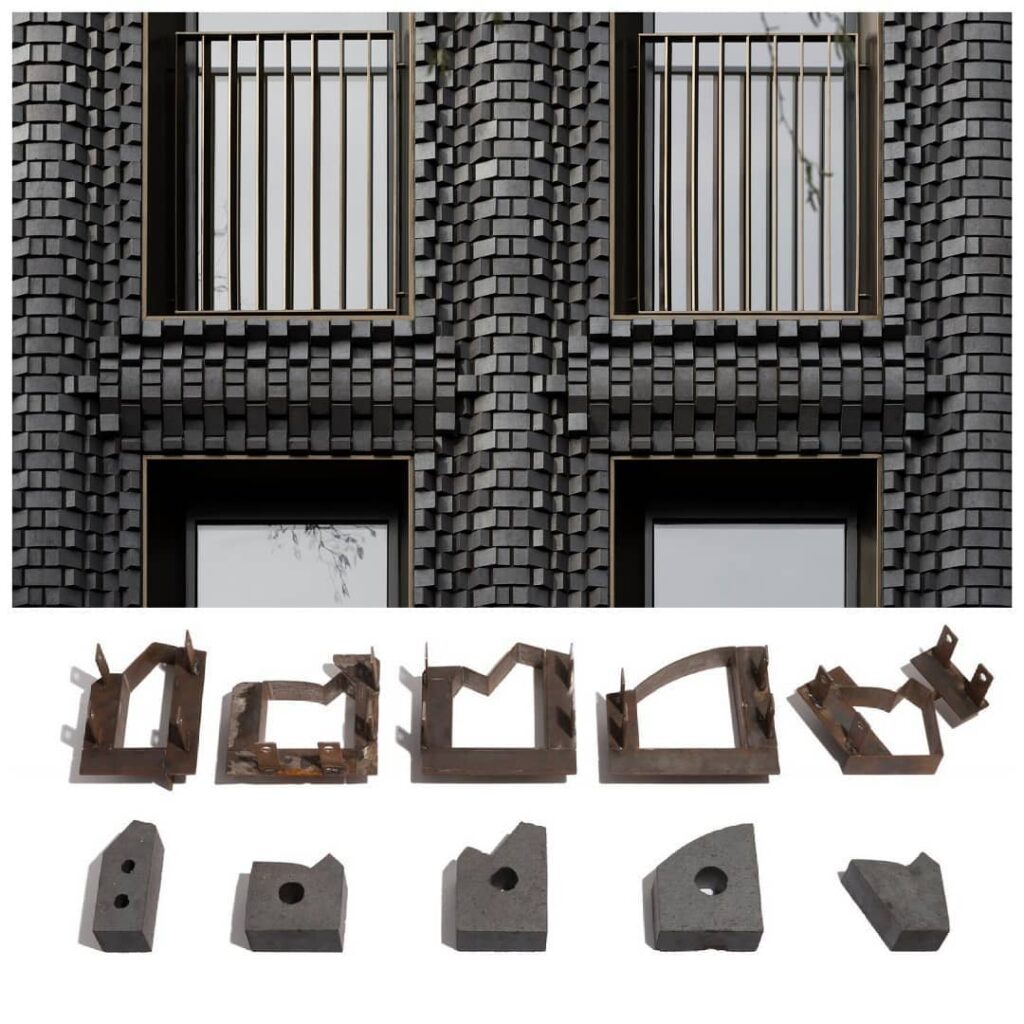

A great example of creatively using traditional materials in non traditional ways.

Making sure that the bespoke brick shapes achieve both visual and structural performance was a challenge. To overcome this detailed models were creative through iterative process ensuring the requirements.

.

The firm modeled 14 brick types and worked closely throughout the research and development process with brickmakers to iterate forms that would fit together, successfully fire in the kiln, and remain strong when arranged. Once the final forms were decided, handmade metal molds were made and bricks—5,000 of them—were cast. .

The intensive modeling process allowed the designers to control the placement of each individual brick, and installers were given 3D files so they could align each of the rows correctly, which, due to the unusual nature of the structure, required millimeter-level accuracy and specific adaptations for each region of the facade. Between the windows, steel trays were necessary to support the bricks, but installers had to expertly align them so that the frames’ edges would be hidden. Similarly, the layout had to be crafted in such a way that holes within the bricks that help with their load-bearing ability were hidden despite the many odd angles they were placed at.

The bricks were made of Staffordshire Blue Clay and were fired in oxidation to create the matte finish. Building the 5,000-brick “landscape” took three months. “The fabrication team used 1:1 printed templates that set out the number, typology, and location of each brick,” explained the firm, going on to say that the 188 templates acted as a sort of “construction manuscript.”

Details from Dezeen.

Photography is by Gilbert McCarragher.

Share:

Related Posts

Liverpool Paseo Queretaro Facade

Project: Liverpool Paseo Queretaro FacadeArchitects: @migueldelatorrearquitectosLocation: Santiago de Queretaro, Mexico 2017Manufacturers: Nucleos IntegralesPhotography: Jaime NavarroThe Project is located at Paseo Querétaro Shopping Center, in the city

The Public Gallery, West Bromwich

The Public Gallery, West BromwichArchitect: Alsop ArchitectsBuilding Envelope Subcontractor: Richardson Roofing Ltd Must be the most controversial project of the area due to the over